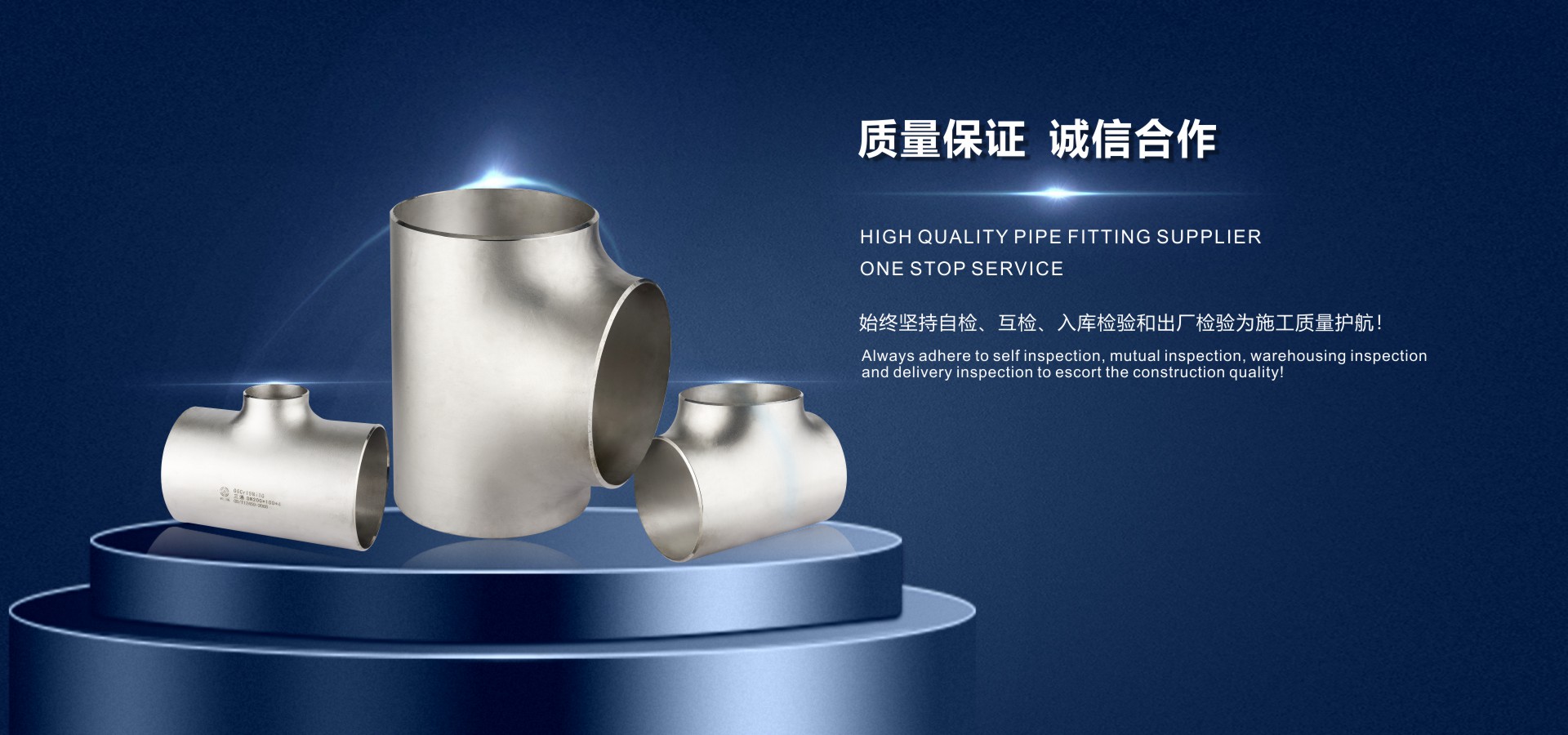

Everyone is responsible, road check, each qualified, customer satisfaction". Our company is always following the quality objective, through this tenet,, within the company to establish a set of effective operation of quality assurance system and a complete set of strict product testing method (X-ray flaw detection, magnetic particle inspection, penetrating agent imitation, chemical analysis, physical performance test, etc.), Strictly manage all processes from reinspection of raw materials to inspection of finished products, effectively ensure the quality of products, products by the State Bureau of Technical supervision spot check qualified, the state issued by the relevant departments of pressure pipeline components safety registration certificate.

Product introduction

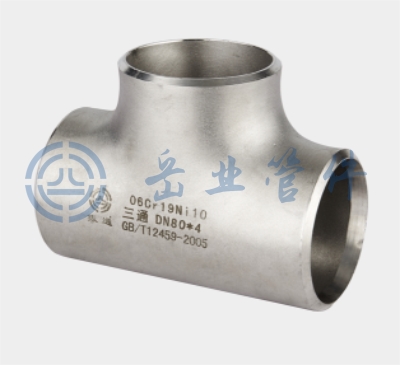

Main production to austenitic stainless steel, dual phase steel, copper alloy, alloy steel, titanium alloy material such as all kinds of pipe fittings, flanges Production of more than 3000 tons

Production Equipment

Advanced production technology, first-class production testing equipment, modern management mode, high-quality management team, high proportion of professional and technical personnel, complete

Pay close attention to more industry news

What are the forming processes of stainless steel pipe fittings?

For stainless steel pipe fittings, in the production process, reasonable molding process is very important, so what is the molding process of stainless steel pipe fittings?

What are the components of stainless steel pipe fittings?

Stainless steel pipe fittings have a good use in many industries, so what are the components of stainless steel pipe fittings?